Ultrasonic Welding Systems

Theory to Practice

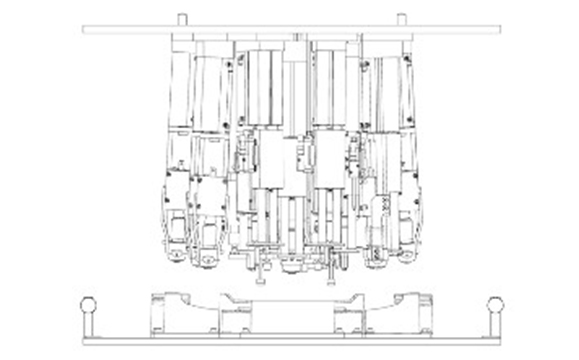

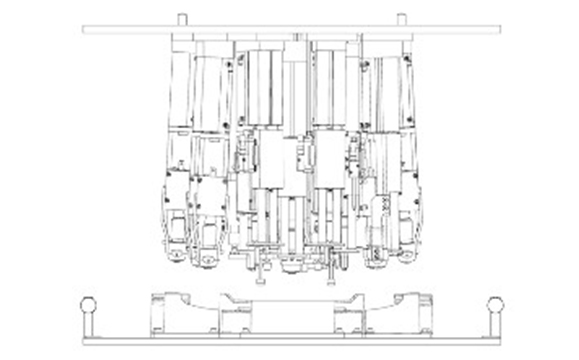

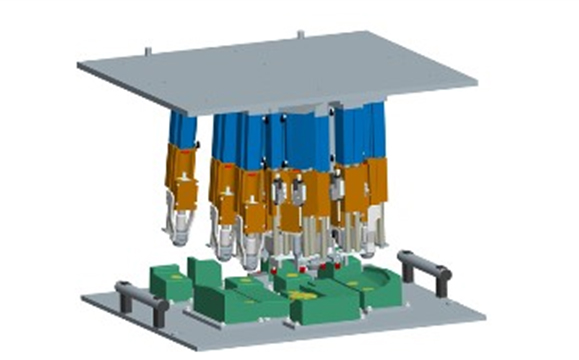

CAD design of tool change module with multiple weld heads and fixtures

3D collision analysis of individual actuators, part clamps and welding tools

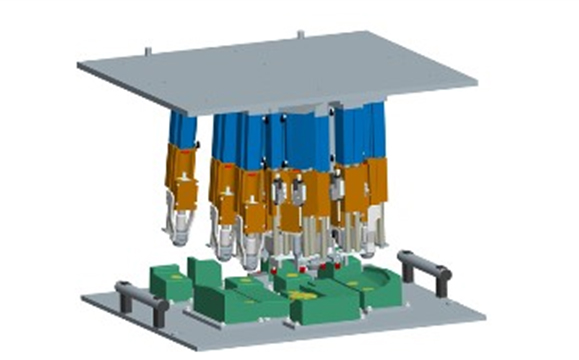

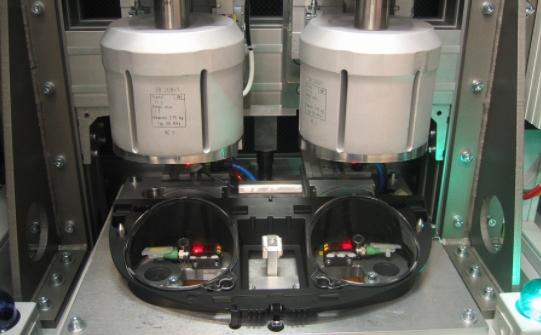

Tool change module with integrated fixture on a custom ultrasound machine ready for production

Service Scope

Automated Equipment Design

Development of machine concepts for custom applications

Optimize loading and assembly sequence

Check assembly order

Evaluation of economic aspects of automation installations

Automation related design

Full implementation of customer requirements and product specifications

Integrate product pretest results into machine concept

Support crash 3D analysis

Mechanical design and PLC related interface definition

Ultrasonic Tool Optimization Design (FEM)

Consulting for the integration of ultrasonic welding systems into new or existing production systems

Configuration of automation equipment

Machine design optimized for production cycle times

Development of options and accessories to support the mass production process

Design a suitable consumable tool change solution

Quality Monitoring Solution

TOOL Design

FEM Calculations for optimized Ultrasonic Horn

We use state-of-the-art FEM software for Horn development. It shows the Horn's ultrasonic amplitude and any material stresses that occur.

Result: maximum efficiency, uniform distribution of weld amplitude and high level of stability.

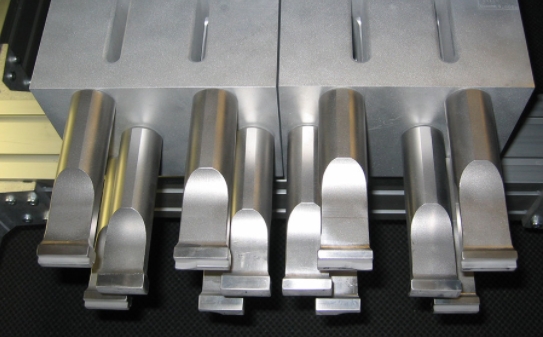

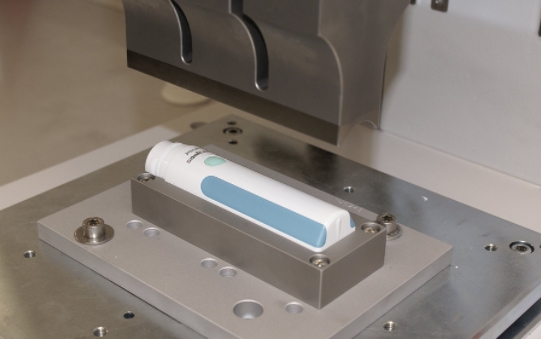

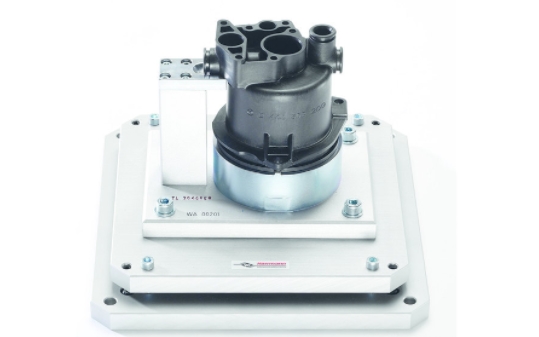

Examples for Horns & Nests