HiS T

본문

HiS VARIO T system

Ultrasonic welding system for integration in automated production lines. The HiS VARIO T is the perfect solution for terminal applications. Quick changes of the applications are as possible as the safe and easy replacement of weld tools. Sophisticated functionalities and interfaces ease the integration of the work station throughout the production line. Production safety and quality through precision come first.

Precise alignment

Precise alignment

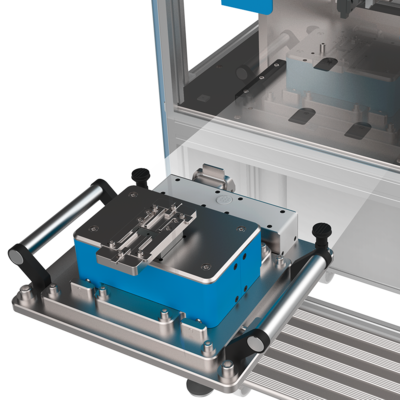

Safe and quick application change

Safe and quick application change

Safe and repeatable tool changege

Safe and repeatable tool changege

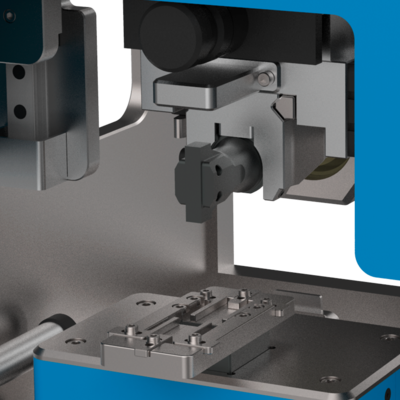

Precise alignment

■ Quick, safe and precise adjustment adjustment of the individual functional elements, such as the sonotrode position and interchangeable fixture

■ Optimum support of the sonotrode in the tooling mount for reproducible weld results

Quick and easy application change

■ Innovative equipment concept for a wide range of parts and applications

■ Equipment indexed and changeable with plug-in type connections

■ Rapidly exchangeable format sets

Reproducible and safe tool change

■ Innovative design of sonotrode and tooling mount guarantees stability

■ Precise sonotrode change in a few minutes

■ Clamping system for changing the tooling mount

Modularity and flexibility

Basic functions

■ Sonotrode cooling

Optional auxiliary functions on a modular basis:

■ Part ejector

■ anvil cooling

■ terminal damping

■ converter cooling

Selection of different weld force ranges

■ Weld forces of up to 6000 N

Fieldbus interfaces:

■ EtherCAT

■ PROFINET IO

■ EtherNet/IP

■ and others

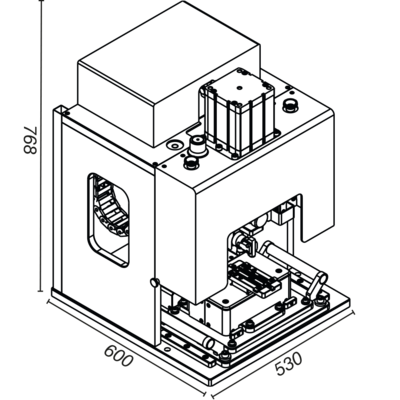

Space requirement (footprint)

■ Compactness and small size

■ Free feed options with automation

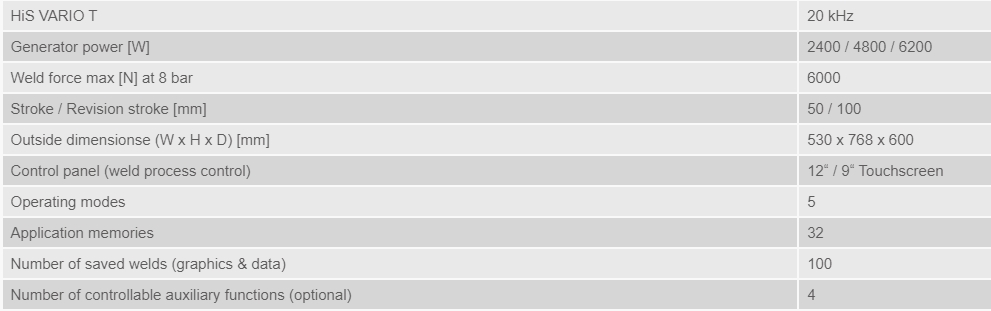

Technical data

- 이전글ULTRAMETAL digital 21.08.31

- 다음글HiS W 21.08.31