MICROBOND CSI SYSTEMS

본문

MICROBOND CSI SYSTEMS

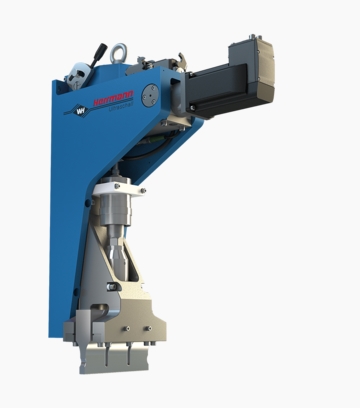

The MICROBOND CSI system, consisting of the actuator, controller and high-performance generator guarantees consistent weld quality. A reliable and at the same time highly precise mechanical system allows a gap stabilization with the patented gap control system Microgap. Control and visualization of this continuous joining process is performed by the MICROBOND controller. Thanks to consistent amplitude and high continuous ultrasonic power output, process speeds of up to 800 m/min can be realized.

20, 30 and 35 kHz operating frequency

20, 30 and 35 kHz operating frequency

600 – 4,800 W generator power

600 – 4,800 W generator power

60 – 4,000 N weld force

60 – 4,000 N weld force

High generator power, rigid sonotrode support and the precise control of high weld forces offer optimal solutions for cross seal and laminating applications.

MICROBOND CSI SYSTEMS

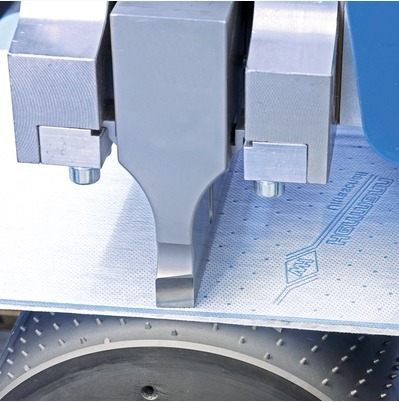

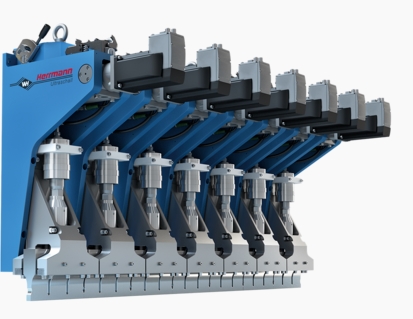

The CSI variants of the MICROBOND product line are characterized by their modular extension options and enable operating widths of several meters. Thanks to the rigid CSI support and the trapezoid sonotrode geometry it is possible to install sonotrodes at minimum distance to one another. The result: a homogeneous end product without disturbing interruptions.

- No sonotrode offset necessary

- Individual control of single weld units

- Expansible production widths

- No distortion of the web material

Weld process control

Herrmann Ultraschall focuses on maximum transparency in the weld process. Only in this way is it possible to understand, control, and monitor the ultrasonic joining process. Prevention of redundant rejects, reduction of standstill time, and high availability guarantee an economical manufacturing process. Thanks to the mobile MICROBOND Control tablet, the process can be monitored, assessed, and optimized directly at the weld station.

- Process visualization of all relevant welding parameters

- Process-oriented user guidance with intuitive operability

- Real time quality control

- System safety for the protection of man and machine

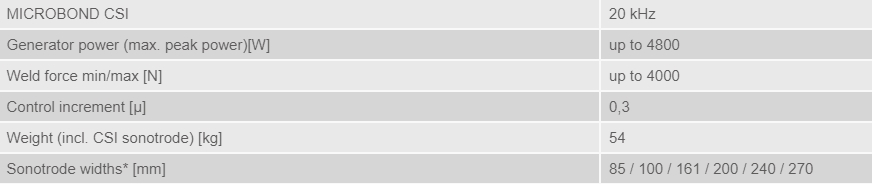

Technical data

More on CSI support

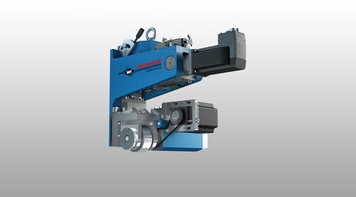

The continuous welding of web material requires the highest level of precision. Even slightest variations in the gap width between the sonotrode and the rotary anvil of a few µm have an influence on good or suspect welds. Mechanical influences such as axial and cross-directional weld forces or temperature-related material expansion must be understood and controlled in detail.

These factors are compensated by the patented CSI support, which ensures that the sonotrode is directly clamped at the vibration node (vibration-free point) by means of a decoupled mechanical system. This reliable support technology maintains consistent weld results, even in applications with large contact pressure areas or intermittent cross-directional weld surfaces.

MICROBOND technology – optionally expandable

The CSI variants of the MICROBOND product line are characterized by their modular expansion options. Operating widths of several meters can be realized without any problems. Thanks to the rigid CSI support and the trapezoid sonotrode geometry it is possible to install sonotrodes at minimum distance to one another. The result: a homogeneous end product without disturbing interruptions.

- No sonotrode offset required

- Individual control of single weld units

- Compensation of anvil drum bending

- No distortion of the web material

This may also be of interest to you

MICROBOND RS SYSTEME

For controlled and complex processes with high speeds, soft welding for small to medium operating widths.

MICROBOND Control

For simpler applications with a large process window, medium speeds and large operating widths.

Industry solution HYGIENE

Diapers, femcare and care products: Our application solutions in the field of HYGIENE at a glance.

- 이전글MICROBOND RS SYSTEM 21.09.01