HSG handheld ultrasonic welder

본문

Handheld ultrasonic welder HSG

The welder can be used to join and reshape thermoplastic materials ultrasonically. This offers enormous advantages both technically and economically.

35 kHz operating frequency

35 kHz operating frequency

1000 W generator power

1000 W generator power

Quadruple MULTIPLEXER

Quadruple MULTIPLEXER

The most simple way of welding thermoplastic materials with ultrasonics is with a handheld ultrasonic welder. The welders are excellently suited to use in prototype building, the processing of single pieces, small series, and repairs. Whether spot welding, swaging, staking or cutting– the hand tool HSG is easy to operate, has variable power ratings, and can be equipped with all common sonotrode types (35 kHz).

Handheld ultrasonic welder HSG

The ergonomic product design and low weight of the handheld ultrasonic welder guarantee fatigue-free work. Without major modification or rewiring, it can be quickly and simply supplemented with a built-in multi-finger switch. The handheld ultrasonic welder and sonotrode are kept safe in the HSG MobileCase. This provides optimal storage for both the generator and connector cable. All common sonotrodes can be properly installed with the accompanying installation tools.

Handling variations are minimized thanks to the ultrasonic generator DYNAMIC digital control 1000 M with built-in time / energy / power switch-off. The freely programmable switch-off includes intelligent technology for better-quality and repeatable weld results.

- Can be quickly retrofitted

- Ergonomic handling

- Programmable energy switch-off

- Simple tool change

- Wide range of accessories

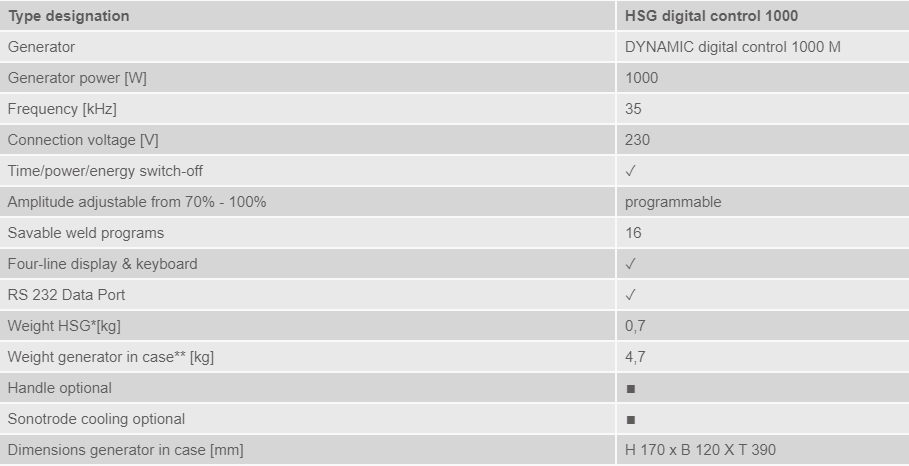

Technical data

- 다음글Punching and sealing systems MPW 21.08.30