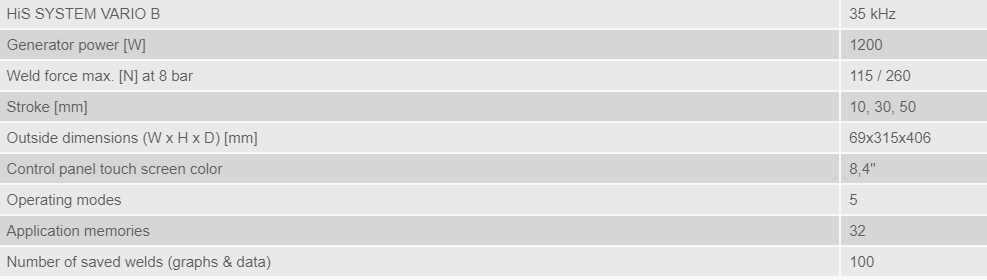

HiS B 35 kHz

본문

HiS SYSTEM B 35 kHz

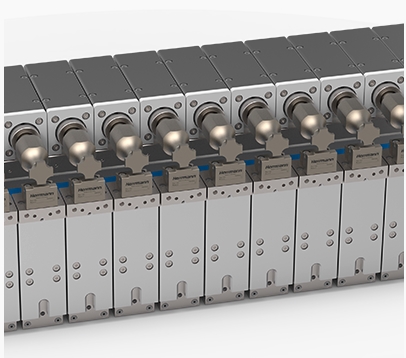

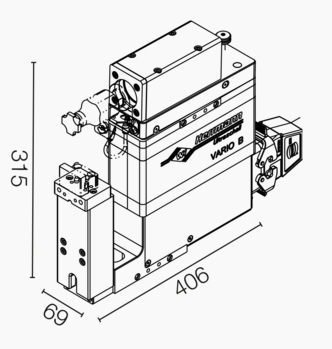

HiS VARIO B can be easily integrated into production lines and impresses users with its compactness and accessibility. All elements for fast tool change and production start-up have been rethought and considerably reduce change over and maintenance times. Co

Precision

Precision

Easy and fast tool change

Easy and fast tool change

Modularity and flexibility for automation engineers

Modularity and flexibility for automation engineers

Precise, low weld forces

- Newly developed rocker system (force range of 5 - 260 N)

- High degree of reproducibility of weld force in the lower force range

- Sequential drive concept

Easy and fast tool change

- Indexed tool change system

- Optimum accessibility

- Tool change possible both inline and outside

- Accurate sonotrode change in just a few minutes

Modularity and flexibility for automation engineers

- Compact arrangement of weld modules

- Mechanical interfaces at several points

- Individual main stroke and weld force can be selected

- Various fieldbus interfaces for communication (EtherCAT, ProfiNet PROFINET IO (RT), EtherNet/IP and others)

-More function and software options (sonotrode cooling, converter cooling, DataRecorder for data analysis)

Footprint

- Industry-leading compactness and small size

- Free feed options with automation

Technical data

- 이전글HiS W 21.08.31

- 다음글HiS B 20 kHz 21.08.31